| Company Name | View Well International (HK) Co., Ltd. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Image | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| About Us | Our story began in Shenzhen, South East China, in 2003. Mechanical engineer Chris Chang, now CEO, did what others couldn′t and provided bespoke mechanical part solutions for the marine navigation company, Raymarine. After exceeding all customer expectations, word quickly spread, recommendations were made and View Well International was born. Today, View Well is privileged to help numerous companies worldwide, manufacturing ISO and IATF certified mechanical part solutions and providing full supply chain management to an array of industries. The future looks bright. We are proud of our long standing relationships with blue chip companies such as GE, IBM and Tesla and top contract manufacturers such as Flextronics, Foxconn and Jabil. We are also equally proud of our employees, it is because of them that View Well continues to be recommended. Solutions: CNC milling and turning, metal stamping, sheet metal, tooling, extrusion, die casting, forging, sintering, gear machining, gearbox assembly and finishing. Further solutions available upon request. Capabilities CNC milling plant, CNC turning plant, stamping plant, Power Meter components plant, medical equipment plant. ISO9001: 2015, IATF6949: 2016 and ISO13485: 2016 certified separately. Applications: Aerospace, marine, metro, motorbike, automotive industries, instruments & meters, office equipment, home appliances, medical equipment, electrical & electronics, telecommunications, fire detection system etc. Numbers: Established 2003. Over 1000 employees with 80 ′expert in their field′ engineers. 2016 turnover of $62m. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tel | Login to view | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fax | Not set | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Name | Mr. Rich Han | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Address | 3D1904, Cloud Park, No. 2018 of Xuegang Rd, Bantian Street, Longgang District, Shenzhen, China | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not set | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Products Details |

= Capability & Advantage:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Web Site | Login to view | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B2 B Website | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B2 C Website Shop | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Member Type | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

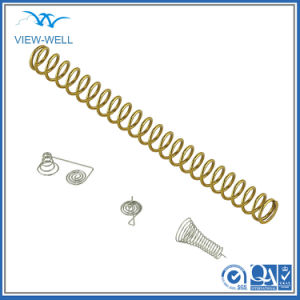

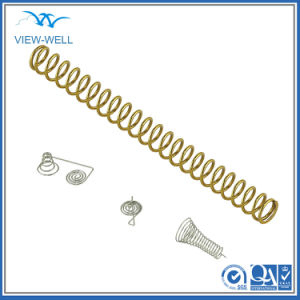

| Mainly Products | Customized Metal Spring Clip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||