| Company Name | Hangzhou Bright Rubber Plastic Product Co., Ltd. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

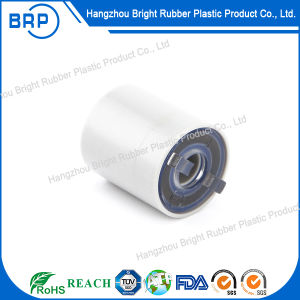

| Image | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| About Us | Hangzhou Bright Rubber Plastic Product Co., Ltd. Was established in 2004. It is located in hangzhou city, zhejiang Provice, China. Our company is engaged in manufacture Rubber and plastic parts. Our parts main include molded rubber parts, Extrusion Rubber parts, Extrusion silicone/silicone sponge tube/strip, Injection plastic parts, Extrusion plastic parts, Rubber sponge parts, PVC dipping, The main rubber raw material is EPDM, Natural Rubber, SBR, Nitrile, Silicone, Fluorosilicone, Viton(FKM), FFKM, Aflas, Neoprene, Urethane(PU), Polyacrylate( ACM), Ethylene Acrylic(AEM), Santoprene, HNBR, Butyl(IIR), LSR; The main plastic raw material is PP, PA, PE, POM, PC, PVC, PS, TPE, TPR, TPU, TPV, UHMWPE, HDPE, LDPE, Our factory passed IATF16949. We make parts as per material standard ASTM D2000, SAE J200, Tolerance as per RMA, N FT47-001, DIN 7715, DIN ISO 3302-1, Our material can meet FDA, LFGB, CE1935/2004, Medical grade, RoHS, REACH, UL94 HB-V0 Grade, FMVSS302. NSF61, WRC, KTW, W270, WRAS. Our core management team has rich experience and deep understanding of rubber and plastic development. With mature and stable management team, advanced equipment and leading technology, experienced marketing team, a good reputation among our customers, the Group is making every effort to create the new brand of rubber, plastic products, metal products, mold processing in the world. "leadship through quality and service, To create value for customers is creating a future for ourselves" as our motto. Welcome overseas friends to visit to us! Looking forward to your support more! | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tel | Login to view | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fax | Not set | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Name | Ms. Silvia Si | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Address | 3-1102 Jinsedatang, DingQiao,Jianggan District, Hangzhou China 310021, Hangzhou, Zhejiang, China | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not set | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Products Details |

Product show

Other main products: ADVANTAGED SERVICE TO YOU: 1.Lower freight of sample or goods by DHL, as we have DHL account with bigger discount. 2. Lower price from less management cost, less labor cost and land cost from our new plant. 3. Less FOB cost as it is only 1~3 hours drive from our factory to Ningbo or Shanghai port and airport. 4. More solution for plastic/rubber material and prodution as our boss and engineers have 30 years of experiences in rubber plastic industry. 5. More Effective service: prompt reply for your e-mail within 6 hours, good solution for any problems within 12 hours. 6. More advantaged products: rubber molded/injection parts, plastic injection parts, and silicone extrusion parts.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Web Site | Login to view | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B2 B Website | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B2 C Website Shop | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Member Type | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mainly Products | Standard Size Existing Mold Natural Rubber Shock Absorber | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||